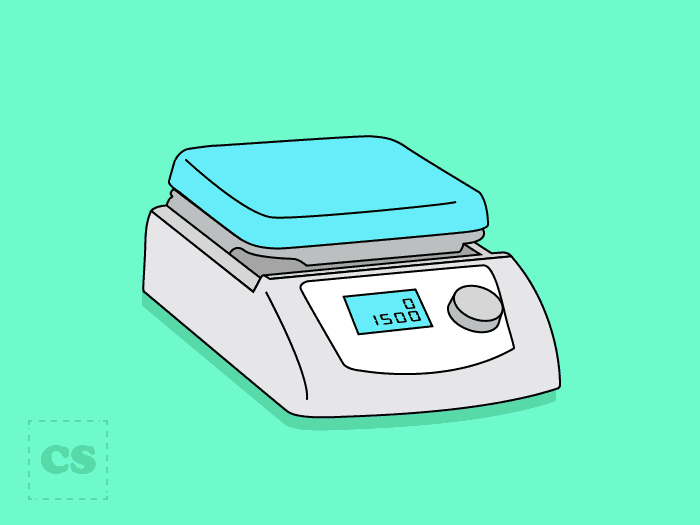

The hot plate is an essential, portable, table-top machine used for certain lab procedures which require heating samples.

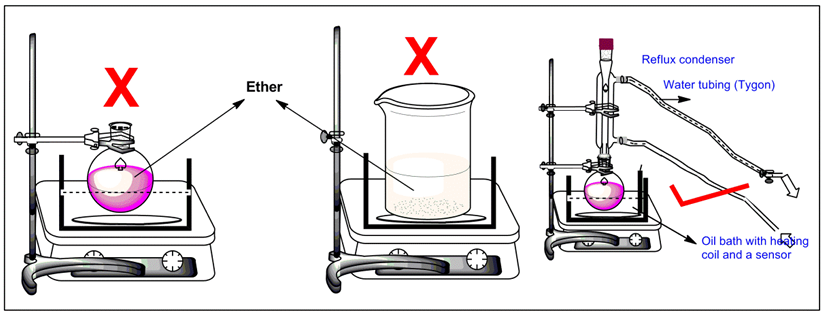

Hot plates have a flat surface with an internal heating system. The device can reach a temperature as high as 350℃, hot enough to ignite a spectrum of low-boiling solvents like pentane, hexane, diethyl ether, acetone, and low-boiling petroleum ether.[1] Thus, these substances should never be heated with hot plates, especially in an open vessel.

Figure: An image of a hot plate without a stirrer.

Some hot plates come with a magnetic stirrer, making it easier for the heated liquid to swirl continuously and form a homogenous mixture. For example, adding agar to a medium and gently heating it requires that the mix be stirred continuously until completely dissolved.

Hot plates are preferable to hot baths in student labs because hot baths are dangerous and can overheat, spill, or ignite.[2] Also, it takes more time to cool down, requires expensive mantles, and doesn’t work for all sizes of flasks.

Based on the design, hot plates are of three types:[3]

Based on the material used in making a hot plate surface, there are:[3]

Here are factors you should consider when choosing hot plates for your lab:[4]

The temperature range of different hot plates available on the market is within 250-550℃.[4] However, it’s always recommended to choose an instrument with a temperature range higher than required to heat the sample.

For example, if you need to heat your samples at 250℃, go for a hot plate that provides a maximum temperature of 300℃ or more.

Also, the working temperature of hot plates is influenced by the plate surface’s material:[5]

Hot plates are available in different sizes and dimensions. It’s recommended to use a plate larger than the size of the vessel you will be working with, though there are several highly efficient mini-hotplate stirrers up for purchase.[5]

However, a larger plate has high power consumption and requires a three-phase power supply.[5] Therefore, purchase the instrument while considering the facilities of your lab.

Hot plates come with two types of temperature control:

If you seek temperature uniformity, purchase a digital hot plate with a stirrer. They are excellent in heat distribution.[5] The temperature uniformity can be checked using a temperature meter and a surface tracker.

The capacity of the sample subject for heating is an essential factor when purchasing a hot plate. The capacity of the device available on market ranges from 20 liters to 200 liters.[4]

Safety is a primary concern while working with instruments like hot plates. A range of safety features that come with the device include:[4]

If working with a viscous sample, then purchase hot plates with high-powered drive magnets. Note that a bigger-sized hot plate can’t handle the high viscosity of a sample. A unit with magnetic coupled strength reduces the chance of the stir bar spinning out.[4]

Hot plates are not as dangerous as open flame heating methods. However, there are certain precautions that you need to take when using the equipment:[6]

Figure: An illustration of the right approach of using a hotplate while heating flammable organic solvents.[6]

Hot plates are an essential lab instrument used for heating lab materials and samples. There are several types available in the market, such as those with and without stirring systems. The hot plate system with a stirrer provides more temperature uniformity while heating samples.

Before purchasing the device consider factors like the size, capacity, safety features, and temperature control to procure the right equipment for your labs.

At Conduct Science, we provide you with a range of highly-advanced hot plates with all the safety features intact.