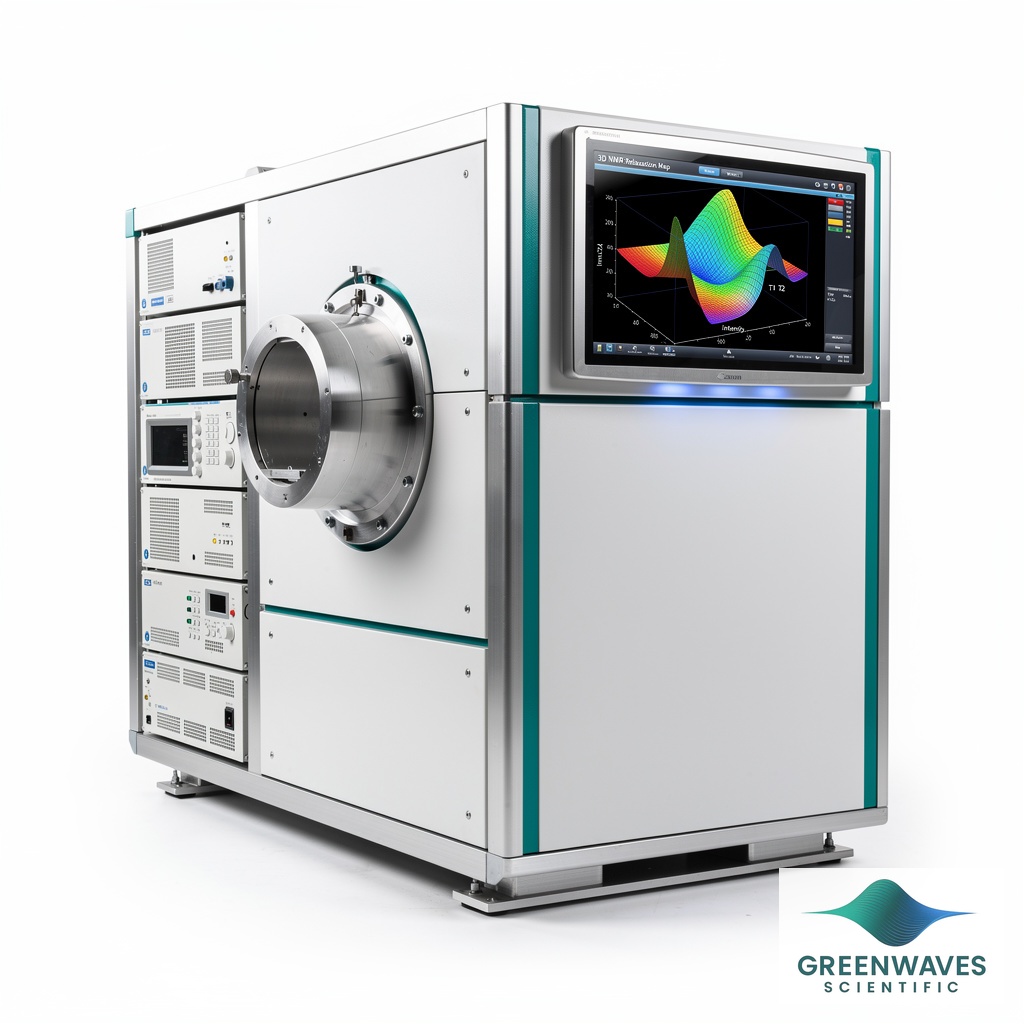

Ultra-low-field NMR analyzer operating at 0.05 T (2 MHz) designed for reliable T1, T2, and T1-T2 correlation measurements on petroleum core samples containing ferromagnetic minerals.

The Ultra-Low-Field Multidimensional NMR Analyzer operates at 0.05 T (2 MHz) using permanent NdFeB magnets to provide reliable nuclear magnetic resonance measurements on core samples containing ferromagnetic minerals. Standard high-field NMR systems suffer from significant measurement artifacts when analyzing samples with magnetite, hematite, pyrite, and other iron-bearing minerals due to internal magnetic field gradients and enhanced relaxation rates. This ultra-low-field approach minimizes magnetic susceptibility effects while maintaining analytical capability for T1, T2, and T1-T2 correlation measurements.

The system features a 110 mm bore diameter to accommodate standard petroleum core samples and enables multidimensional NMR analysis for fluid identification and porosity characterization. Applications focus primarily on unconventional reservoir characterization where ferromagnetic mineral content prevents accurate analysis using conventional high-field instruments. The 2 MHz proton frequency matches field conditions used in well-logging tools, providing direct correlation between laboratory and downhole measurements.

Nuclear magnetic resonance relaxometry measures the time constants for nuclear spin relaxation following radiofrequency excitation. In porous media, hydrogen nuclei in fluids experience both bulk relaxation and surface-enhanced relaxation at pore walls. The T1 (spin-lattice) relaxation reflects energy transfer to the lattice, while T2 (spin-spin) relaxation reflects magnetic field inhomogeneity and molecular interactions. The T1/T2 ratio provides information about pore surface area to volume ratios and fluid properties.

Ferromagnetic minerals create localized magnetic field gradients that accelerate relaxation rates and distort measurements in high-field systems. At ultra-low field strengths (0.05 T), magnetic susceptibility effects are significantly reduced because the induced magnetization in ferromagnetic phases is proportionally smaller. The permanent NdFeB magnet system generates a stable, homogeneous field across the 110 mm bore diameter, enabling reliable relaxation measurements even in samples with substantial iron content.

Multidimensional NMR correlates T1 and T2 measurements to create two-dimensional relaxation maps that distinguish different fluid phases and pore environments. This approach enables identification of bound versus free water, oil versus water, and different pore size distributions based on characteristic relaxation signatures in the T1-T2 correlation space.

| Feature | This Product | Category Context |

|---|---|---|

| Magnetic Field Strength | 0.05 T ultra-low field with permanent NdFeB magnets | High-field systems typically operate at 1.5-7 T using superconducting magnets |

| Bore Diameter | 110 mm bore accommodates large core samples | Benchtop systems often limited to smaller bore diameters |

| Ferromagnetic Compatibility | Specifically designed for ferromagnetic-sample analysis | High-field systems produce distorted results on iron-rich samples |

| Operating Frequency | 2 MHz proton frequency | High-field systems operate at higher frequencies |

| Maintenance Requirements | Permanent magnet requires no cryogen maintenance | Superconducting systems require liquid helium and nitrogen |

| Multidimensional Analysis | T1-T2 correlation mapping with multidimensional NMR capability | Entry-level systems may offer limited correlation analysis |

This ultra-low-field analyzer addresses the specific challenge of NMR analysis on ferromagnetic mineral-containing samples, offering reliable T1-T2 correlation measurements at 0.05 T field strength with a large 110 mm bore diameter. The permanent magnet design eliminates cryogen requirements while the 2 MHz operating frequency enables direct correlation with downhole logging data.

Perform field homogeneity verification monthly using the provided reference standards and document any field drift over time.

Permanent magnets can experience small field changes with temperature cycling, affecting measurement accuracy.

Monitor ambient temperature stability within ±2°C during measurements and allow thermal equilibration after system power cycling.

Permanent magnet field strength has temperature dependence that affects relaxation time measurements.

Characterize sample ferromagnetic mineral content using XRD or magnetic susceptibility measurements before NMR analysis.

Understanding mineral composition helps optimize pulse sequences and interpret relaxation data in geological context.

Verify sample temperature equilibration for at least 30 minutes before measurement to ensure consistent fluid properties.

Temperature affects fluid viscosity and molecular dynamics, which directly influence T1 and T2 relaxation times.

If T2 measurements show excessive signal decay, verify sample positioning in bore center and check for metallic contamination.

Off-center positioning or unexpected metallic objects create field inhomogeneities that accelerate relaxation rates.

Maintain minimum 1-meter clearance around the permanent magnet assembly and secure all ferromagnetic tools before operation.

Permanent magnets create strong localized fields that can attract ferromagnetic objects and interfere with measurements.

Document sample saturation history and fluid composition when correlating laboratory results with downhole NMR logs.

Fluid properties and saturation state significantly affect relaxation signatures and interpretation accuracy.

Cross-validate T1-T2 correlation results with complementary techniques such as mercury intrusion or micro-CT imaging when possible.

Independent pore structure measurements provide validation for NMR-derived porosity and pore size distributions.

ConductScience provides a comprehensive 1-year manufacturer warranty covering all components with dedicated technical support for installation, calibration, and operation. Extended service contracts available for ongoing maintenance and software updates.

The following papers provide general scientific background on measurement techniques relevant to this product category. They are not validation studies of this specific instrument.

What types of ferromagnetic minerals can this system analyze that high-field NMR cannot?

The system handles samples containing magnetite, hematite, pyrite, chlorite, and other iron-bearing minerals that create magnetic field gradients and enhanced relaxation rates in high-field systems. The 0.05 T field strength minimizes magnetic susceptibility artifacts while maintaining measurement sensitivity.

How does the 2 MHz frequency correlate with downhole logging tools?

The 2 MHz proton frequency matches the operating frequency of most commercial NMR well-logging tools, enabling direct comparison between laboratory core analysis and downhole measurements for reservoir characterization studies.

What sample sizes and preparation are required?

The 110 mm bore accommodates cylindrical core samples up to approximately 10 cm diameter and 20 cm length. Samples require minimal preparation beyond cleaning and ensuring representative fluid saturation. Consult product datasheet for specific sample preparation protocols.

Can the system distinguish between oil and water in tight formations?

Yes, T1-T2 correlation mapping creates two-dimensional relaxation signatures that distinguish different fluid phases based on their relaxation properties and molecular dynamics in confined pore spaces.

What maintenance is required for the permanent magnet system?

Permanent NdFeB magnets require no cryogen maintenance, with primary requirements being temperature stability and periodic field homogeneity verification using reference standards. RF electronics require standard electronic system maintenance.

How long do typical T1-T2 correlation measurements take?

Measurement times vary from 30 minutes to several hours depending on sample properties, required signal-to-noise ratio, and relaxation time distributions. Automated sequences optimize measurement parameters based on preliminary scans.

What data formats are provided for analysis software?

The system outputs relaxation data in standard formats compatible with petroleum industry analysis software. Consult product datasheet for specific file formats and data export capabilities.

Can the system measure very tight rocks with microsecond T2 components?

The ultra-low field approach enables detection of shorter T2 components that may be obscured by magnetic susceptibility effects in high-field systems, though specific detection limits depend on sample properties and measurement parameters.