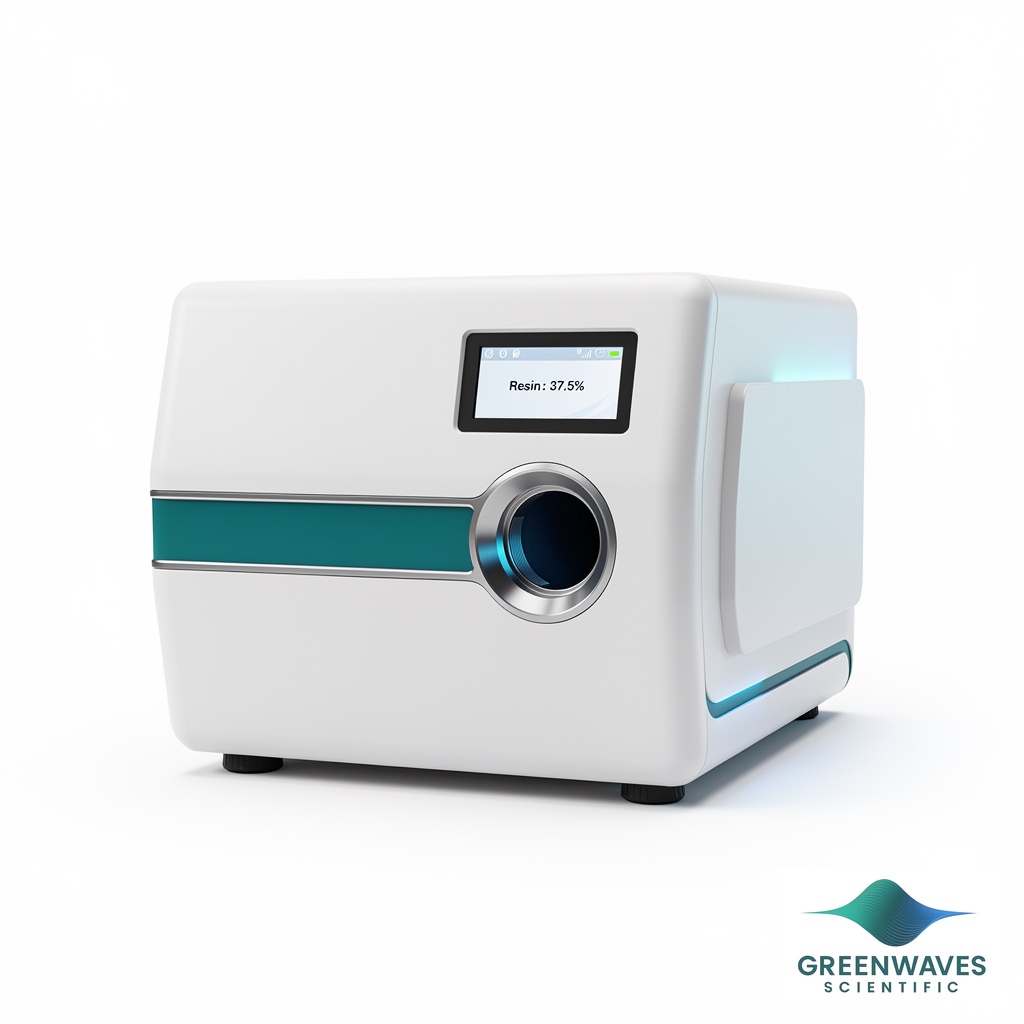

Non-destructive NMR analyzer for quantitative resin content measurement in glass fiber, carbon fiber, and organic fiber reinforced composites, eliminating burn-off testing requirements.

The Resin Content NMR Analyzer provides quantitative, non-destructive analysis of polymer matrix content in fiber-reinforced composite materials through nuclear magnetic resonance spectroscopy. This analytical instrument eliminates the need for destructive burn-off or chemical digestion methods, delivering accurate resin content measurements in minutes rather than hours while preserving sample integrity.

The system utilizes 1H NMR spectroscopy to differentiate between organic polymer matrices and inorganic reinforcement fibers, enabling precise quantification of resin-to-fiber ratios across glass fiber, carbon fiber, organic fiber, and reinforced plastic composites. The non-destructive methodology supports quality control workflows in materials science and industrial manufacturing where sample preservation is critical for downstream testing or production validation.

Nuclear magnetic resonance spectroscopy detects the magnetic properties of atomic nuclei when placed in a strong magnetic field. In composite analysis, the instrument applies radiofrequency pulses to excite 1H nuclei in polymer matrices while discriminating against inorganic reinforcement fibers. The resulting NMR signal intensity correlates directly with the hydrogen content of the organic resin phase.

The analyzer measures relaxation times and chemical shifts specific to different polymer types, enabling identification and quantification of resin content independent of fiber composition. Glass fibers, carbon fibers, and other inorganic reinforcements produce minimal NMR signals, creating a clear contrast with the organic matrix. Signal processing algorithms calculate resin percentages by comparing sample spectra against calibration standards of known composition.

Data acquisition occurs at room temperature without sample preparation, chemical solvents, or high-temperature treatments. The measurement volume encompasses the entire sample, providing bulk composition data rather than surface-limited analysis, ensuring representative results for heterogeneous composite structures.

| Feature | This Product | Category Context |

|---|---|---|

| Analysis Method | Non-destructive NMR spectroscopy | Entry-level systems often rely on destructive burn-off or chemical digestion methods |

| Measurement Time | Results in minutes per sample | Traditional methods typically require 2-4 hours including preparation and processing |

| Material Compatibility | Glass fiber, carbon fiber, organic fiber, and reinforced plastic composites | Limited models often restrict analysis to specific fiber types or matrix systems |

| Operating Temperature | Room temperature operation | High-temperature furnace methods require 600-900°C processing |

| Chemical Requirements | Chemical-free analysis | Acid digestion methods require corrosive chemicals and specialized waste handling |

The analyzer combines non-destructive NMR technology with multi-material compatibility to provide rapid, accurate resin content analysis across glass fiber, carbon fiber, organic fiber, and reinforced plastic composites. Room temperature, chemical-free operation distinguishes this approach from traditional destructive methods while maintaining quantitative precision required for materials research and quality control applications.

Store calibration standards in sealed containers with desiccant to prevent moisture absorption that could alter reference NMR signals.

Consistent calibration standard properties ensure long-term measurement accuracy and traceability.

Clean measurement chamber weekly with isopropanol to remove composite dust and resin residues that may accumulate during routine use.

Contamination in the measurement chamber can produce background signals that affect quantitative precision.

Allow samples to equilibrate to room temperature for 30 minutes before measurement, especially when transitioning from cold storage.

Temperature variations can affect NMR signal intensity and relaxation times, leading to measurement errors.

If signal-to-noise ratios appear low, verify sample positioning in the measurement chamber and check for electromagnetic interference sources nearby.

Proper sample placement within the magnetic field homogeneous region maximizes signal quality and measurement precision.

Run duplicate measurements on critical samples and report average values with standard deviation to demonstrate measurement reproducibility.

Replicate analysis provides statistical confidence in results and identifies potential sample heterogeneity issues.

Maintain minimum 1-meter clearance around the analyzer to prevent interference with pacemakers and magnetic storage devices.

Strong magnetic fields can affect medical devices and damage magnetic storage media, requiring appropriate safety protocols.

Document sample history including manufacturing date, storage conditions, and previous testing to correlate with resin content results.

Comprehensive sample documentation enables correlation of composition data with processing parameters and performance characteristics.

Verify calibration using an independent standard sample monthly to detect any systematic drift in instrument response.

Independent verification ensures continued measurement accuracy and identifies when recalibration procedures are required.

ConductScience provides a comprehensive 1-year manufacturer warranty covering parts and labor, with technical support available for installation, calibration, and troubleshooting assistance.

The following papers provide general scientific background on measurement techniques relevant to this product category. They are not validation studies of this specific instrument.

What sample size and geometry requirements must be met for accurate measurements?

Samples should fit within the measurement chamber without mechanical stress or delamination. Optimal sample thickness ranges from 2-10 mm depending on fiber density, with minimum dimensions of 10x10 mm for representative bulk analysis.

How does the analyzer distinguish between different polymer matrix types?

The system analyzes 1H NMR chemical shifts and relaxation times characteristic of specific polymer structures. While total resin content is quantified universally, polymer identification requires comparison with reference spectra for epoxy, polyester, vinyl ester, and other matrix systems.

What calibration frequency is recommended for maintaining measurement accuracy?

Monthly calibration verification using supplied standards is recommended for routine quality control work. More frequent calibration may be required for critical applications or when measuring significantly different composite types than those used for initial setup.

Can the analyzer handle composites with conductive carbon fiber reinforcement?

Yes, the system accommodates carbon fiber composites through optimized pulse sequences and sample positioning protocols that minimize electromagnetic interference while maintaining quantitative accuracy for resin content determination.

What data formats are available for integration with laboratory information systems?

The analyzer exports results in CSV, XML, and PDF formats including raw spectral data, processed results, measurement statistics, and instrument parameters. Custom data export protocols can be configured for specific LIMS requirements.

How does measurement precision compare with traditional burn-off methods?

NMR analysis typically achieves comparable precision to ASTM D2584 burn-off procedures (±2-3% relative standard deviation) while eliminating sample destruction and reducing analysis time from hours to minutes.

What environmental conditions affect measurement reliability?

Temperature stability is critical for maintaining magnetic field homogeneity. Avoid operation near ferromagnetic materials, electromagnetic sources, or areas with temperature fluctuations exceeding ±2°C during measurement sequences.

Can moisture content in composite samples interfere with resin content measurements?

Water absorption can affect quantitative results since moisture contributes to 1H NMR signals. Sample conditioning protocols are provided to achieve consistent moisture equilibrium prior to analysis, or moisture correction factors can be applied based on separate water content determination.