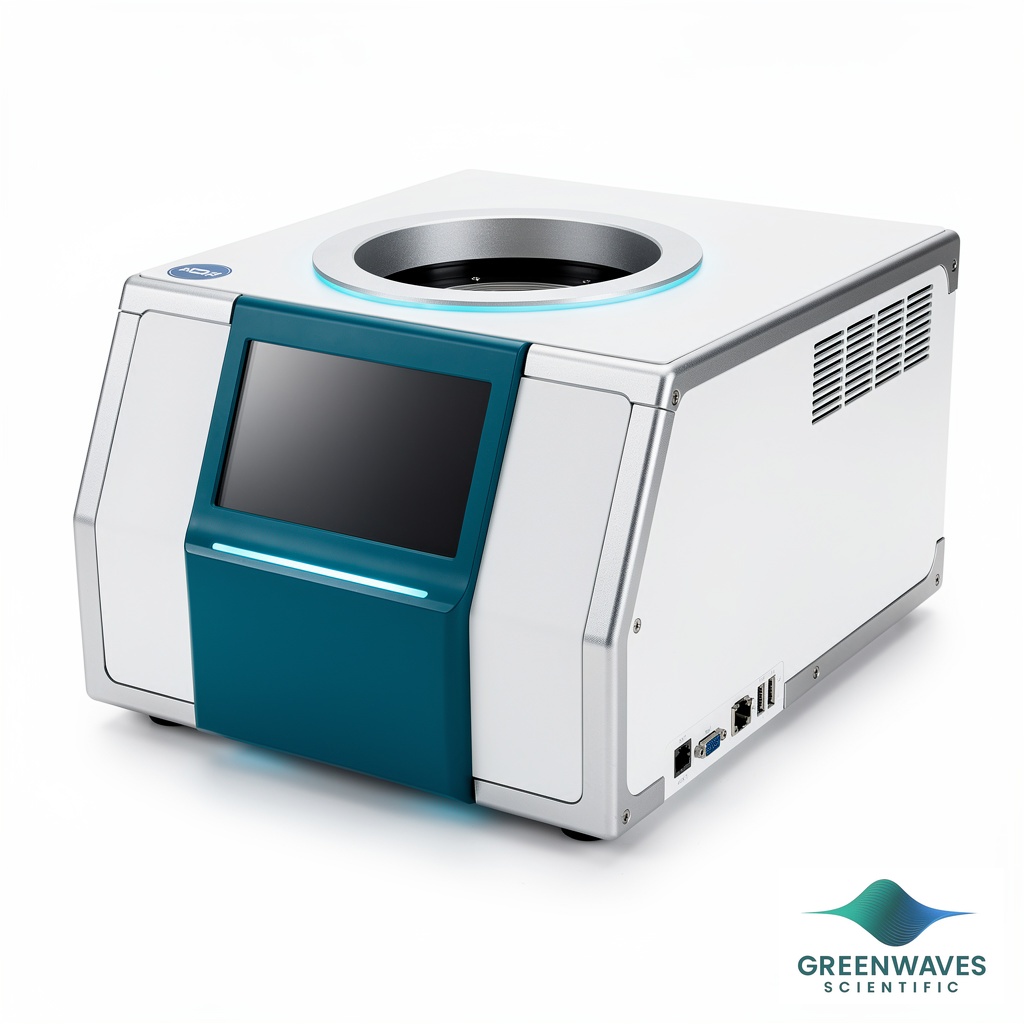

Nuclear magnetic resonance analyzer with 60 mm bore for non-destructive quality assessment of whole food products, available in horizontal and vertical configurations.

The NMR Food Imaging Analyzer (60 mm) utilizes nuclear magnetic resonance technology to provide non-destructive quality assessment of food products. The 60 mm bore diameter accommodates whole fruits, meat cuts, and packaged food products, enabling researchers to analyze internal structure and composition without sample preparation or destruction. Available in both horizontal and vertical configurations, this system supports food science laboratories requiring expanded sample capacity for quality control and process optimization studies.

The analyzer operates through proton NMR relaxometry, measuring T1 and T2 relaxation times to characterize moisture content, fat distribution, and structural integrity. This capability enables monitoring of ripening processes, freshness assessment, and process validation in food manufacturing environments. The system provides quantitative data suitable for research applications in food technology, agricultural science, and quality assurance protocols.

Nuclear magnetic resonance imaging operates by placing samples in a strong magnetic field and applying radiofrequency pulses to excite hydrogen nuclei (protons) in water and organic compounds. When the RF pulse is removed, the protons return to their equilibrium state, emitting detectable signals. The relaxation times T1 (spin-lattice) and T2 (spin-spin) provide information about molecular mobility and local environment of water and fat components.

In food analysis, different tissues and components exhibit characteristic relaxation patterns. Water in fresh tissue has different relaxation properties compared to bound water in aged or processed materials. The analyzer measures these differences to assess quality parameters such as moisture content, fat distribution, and structural integrity. The 60 mm bore allows analysis of intact samples up to 60 mm in diameter, preserving natural structure and avoiding artifacts from sample preparation.

Data acquisition involves applying pulse sequences optimized for food components, collecting signal intensity data, and processing results to generate relaxation maps or quantitative parameters. The system can operate in both horizontal and vertical orientations to accommodate different sample geometries and handling requirements.

| Feature | This Product | Category Context |

|---|---|---|

| Bore Diameter | 60 mm bore accommodates whole fruits and larger food products | Entry-level models often feature smaller bore sizes limiting sample capacity |

| Configuration Options | Available in both horizontal and vertical orientations | Many models offer single configuration limiting sample handling flexibility |

| Sample Capacity | Expanded sample capacity for whole food products | Compact systems require sample preparation or sectioning |

| Application Focus | Specifically designed for food analysis applications | General-purpose NMR systems may lack food-specific protocols |

The 60 mm bore NMR Food Imaging Analyzer provides expanded sample capacity with dual configuration options specifically optimized for food analysis applications. The larger bore diameter and flexible orientation enable analysis of whole food products without preparation artifacts.

Allow samples to equilibrate to measurement temperature before analysis to ensure consistent results.

Temperature variations affect NMR relaxation parameters and can introduce measurement variability.

Perform calibration verification using reference materials similar to your target samples in composition and geometry.

Matrix effects and sample geometry can influence measurement accuracy, making appropriate reference materials essential.

Keep the bore area clean and free from metal contamination that could affect magnetic field homogeneity.

Metal particles or residues can create field distortions leading to measurement artifacts and reduced precision.

Document sample orientation and positioning for reproducible measurements, especially with irregularly shaped products.

Consistent sample positioning ensures measurement repeatability and enables meaningful comparison between analyses.

If signal quality decreases, check for sample movement during measurement and ensure proper sample securing.

Sample motion during analysis creates artifacts and reduces measurement precision, particularly important for longer pulse sequences.

Maintain awareness of magnetic field hazards and remove all ferromagnetic objects before approaching the analyzer.

Strong magnetic fields can attract metal objects creating safety hazards and potentially damaging the instrument.

ConductScience provides a standard one-year manufacturer warranty covering parts and labor, with technical support for installation, calibration, and operational guidance throughout the warranty period.

What sample size limitations apply to the 60 mm bore analyzer?

The bore diameter of 60 mm sets the maximum sample dimension. Samples must fit within this constraint while allowing adequate clearance for positioning. Both horizontal and vertical orientations are available to optimize sample geometry accommodation.

How does measurement precision compare between horizontal and vertical configurations?

Both configurations provide equivalent measurement precision as they utilize the same magnetic field and detection systems. Configuration choice depends on sample handling requirements, laboratory workflow, and sample geometry considerations.

What calibration procedures are required for quantitative analysis?

Consult product datasheet for specific calibration protocols. Standard NMR food analyzers typically require reference material calibration for moisture content correlation and system performance verification at specified intervals.

Can the analyzer detect specific food safety hazards or contaminants?

The system provides structural and compositional information through NMR relaxometry but is not designed for specific contaminant detection. It identifies quality changes that may correlate with spoilage or processing deviations.

What data output formats are available for analysis results?

Consult product specifications for supported data formats. NMR food analyzers typically provide relaxation time measurements, moisture content values, and imaging data in standard scientific data formats.

How does this compare to destructive testing methods for food quality?

NMR analysis provides internal structure information without sample destruction, enabling multiple measurements on the same specimen and preserving samples for additional testing. However, it may require correlation with destructive methods for specific parameter validation.