Reference to this article: ConductScience, Autoclave Sterilizers 101: How They Work Plus Safety Tips (2022). doi.org/10.55157/CS20220717

An autoclave is a machine used in industrial and scientific labs to sterilize or decontaminate items.[1] It applies particular heat under pressure to the machine’s chamber to kill harmful pathogens, such as bacteria, fungi, spores, and viruses in and on the items kept in the autoclave vessel.[1]

The items are autoclaved at a specific temperature for a given time. The procedure induces moisture in steam to transfer heat to destroy the protein structure of contaminants or microorganisms and disinfect the items.

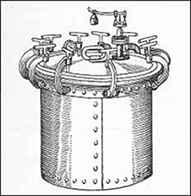

Over time, the autoclave technology has improved from being a basic steam sterilizer to enhanced versions with pre-vacuum cycles and steam-flush pressure-pulse features.

Figure: The first steam sterilizer built by Charles Chamberland in 1880 for medical applications.[2]

The autoclave has a range of applications in areas including dentistry, microbiology, medicine, and veterinary science.[3]

Figure: Advanced research autoclave used today in labs.

This article discusses the working mechanism of autoclaves, materials that can or can’t be autoclaved, and how to use an autoclave safely.

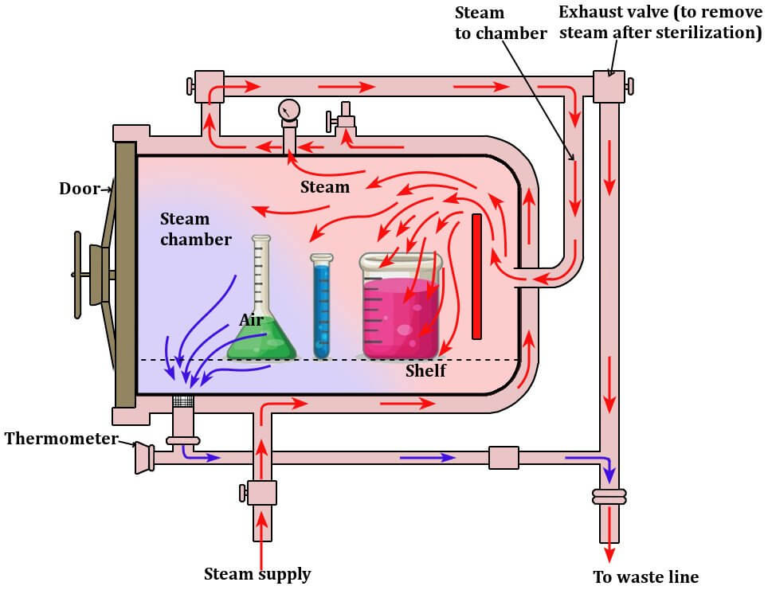

Autoclave works on the principle of moist heat sterilization. It generates saturated steam under a particular pressure to kill pathogens.

Here’s how it works!

Seal the autoclave after the items, including tools and chemicals, are kept in its chamber. Then, remove the air present in the chamber by:[4]

As air is removed, steam is pumped into the chamber at higher pressure, which helps achieve the sterilizing temperature in the given duration.[5] The higher the pressure, the higher the temperature inside the chamber.

Higher pressure in the autoclave’s chamber helps heat penetrate deeper parts of the items in it and cause coagulation of microbial proteins, making them inviable.[5]

Steam is continuously supplied in the chamber to maintain the target temperature once it has been reached.

Normally, a temperature of 121°C at the pressure of 15 psi or 775 mmHg is used in labs to sterilize the equipment, tools, and autoclavable chemicals.[5]

Once the sterilization is over, the autoclave’s chamber releases the pressure through a whistle while the machine’s temperature and pressure return to normal.

Though autoclaves are simple to use, there are certain safety measures you need to observe before running the machine:[5]

An autoclave is an effective way to sterilize equipment, tools, and certain chemicals. However, not all materials can be autoclaved. Therefore, before autoclaving, ensure the material or items can withstand high temperatures and pressure.

Here are some frequently asked questions by autoclave users:

The autoclave sterilization cycle consists of three phases:[3] Purge Phase, Exposure (Sterilization) Phase, and Exhaust Phase – these phases are completed in around 1-1.5 hours.[11]

The autoclave cycle time frame refers to the exposure phase, which varies based on the size, shape, density, weight, and material composition of the items being sterilized.

Autoclave commonly runs at temperatures between 250° F (121° C), 270°F (132°C), to 275°F (135° C).[2] It’s essential to expose the items being sterilized at this temperature for a certain period for complete sterilization.

Yes, it can. When the seal of the autoclave’s door is malfunctioning, the rapid release of extreme heat and temperature trapped inside the chamber can cause an explosion and severe injury to people around it.

An autoclave is a machine used to sterilize tools and liquid media in labs. It applies high pressure and temperature to disinfect the items in the chamber.

It’s mainly used in scientific, medical, and industrial labs to sterilize a spectrum of items. Currently, scientists are working to create sophisticated autoclaves with advanced technology, toughness, better safety, and upgraded features.

Though an autoclave is easy to use, it can be dangerous to work with if handled carelessly. Therefore, it’s essential to follow the safety guidelines that come with the equipment and ensure that only autoclavable items are autoclaved.

Furthermore, regular maintenance of the machine is required because if the door or other parts of the equipment malfunction, the high pressure and temperature can cause an explosion.

Often in such cases, the quality of the autoclave bought also plays a significant role, hence why you must purchase from trusted vendors only.

At Conduct Science, we provide high-throughput and easy-to-use autoclaves at affordable prices – click to shop for the best autoclave for your research!