Microfluidic chips stand out as miniature wonders, enabling precise manipulation and analysis of fluids at the microscopic level. These tiny devices, often built with precise engineering, have transformed various fields, from biotechnology to materials science [1][2]. In this blog, ConductScience will delve into the intricacies of making custom microfluidic chips, exploring their uses, fabrication methods, applications, experiments, and implications.

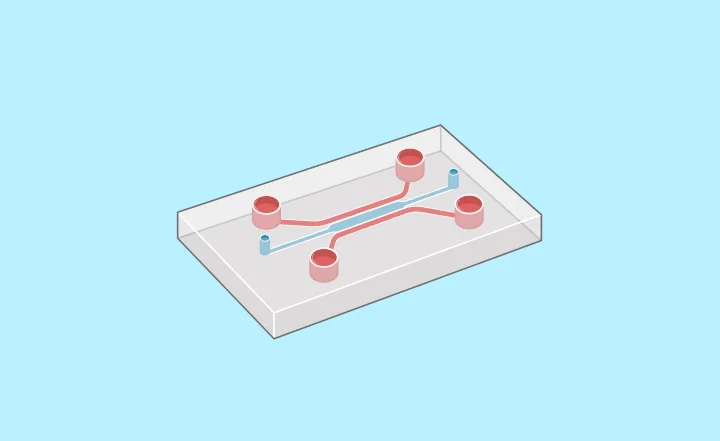

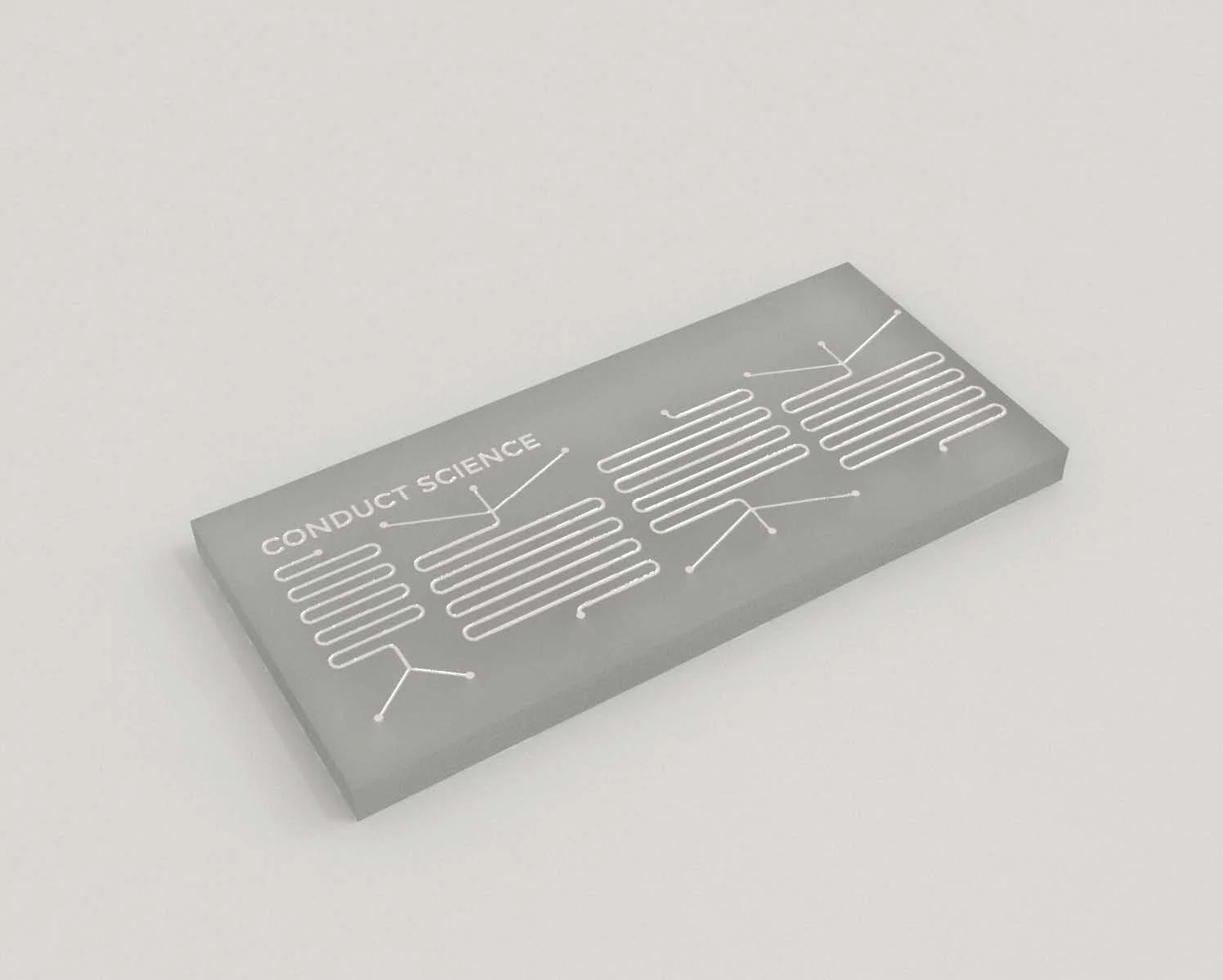

Microfluidic chips, also called lab-on-a-chip devices, are tiny platforms that help with precise handling and analysis of fluids at a very small scale. These chips typically consist of small channels, chambers, and other structures etched or molded onto a small piece of material, often glass, silicon, or polymers.

Figure: Microfluidic Chip

Their uses spread across various areas, including:

Making custom microfluidic chips involves a mix of techniques, including photolithography, soft lithography, 3D printing, and laser micromachining. Here’s a simplified overview:

Custom microfluidic chips have countless applications:

Food and Beverage Industry: Microfluidic devices that can check food and drinks for contaminants, ensuring they’re safe to consume [15].

In a groundbreaking study led by Dr. Li and her team at the Institute of Biomedical Engineering, researchers utilized custom microfluidic chips to investigate the dynamics of drug delivery to cancer cells. The study aimed to address the challenge of optimizing drug dosages to maximize efficacy while minimizing adverse effects.

The custom microfluidic chips were meticulously designed to mimic the complex microenvironment of tumors, including intricate networks of blood vessels and cellular structures. The team integrated microfluidic channels with precise control over flow rates and concentrations to simulate drug transport within these tumor-like environments.

Using advanced microscopy techniques, the researchers tracked the movement of fluorescently labeled drug molecules in real-time as they traversed through the microfluidic channels. This allowed them to observe how factors such as flow patterns, cell-cell interactions, and drug properties influenced drug distribution and uptake by cancer cells.

The results revealed novel insights into drug transport dynamics, highlighting the importance of factors such as convective flow and cellular binding in governing drug delivery efficiency. By fine-tuning the design of the microfluidic chips and incorporating patient-specific parameters, the researchers envisage personalized drug delivery strategies tailored to individual tumor characteristics.

This research, published in the journal Biomedical Microdevices [16], represents a significant step forward in understanding the intricacies of drug delivery mechanisms and holds promise for the development of more effective cancer therapies.

Custom microfluidic chips are powerful tools for scientists and engineers, allowing them to manipulate fluids and analyze tiny samples with incredible precision. From basic research to practical applications in healthcare and beyond, these small devices continue to push the boundaries of what’s possible in science and technology. As fabrication methods improve and new applications are discovered, the future looks bright for custom microfluidic chips and the innovations they’ll bring.

Vanja works as the Social Media and Academic Program Manager at Conduct Science. With a Bachelor's degree in Molecular Biology and Physiology and a Master's degree in Human Molecular Biology, Vanja is dedicated to sharing scientific knowledge on social media platforms. Additionally, Vanja provides direct support to the editorial board at Conduct Science Academic Publishing House.